Asaoti, Faridabad, Haryana

- GST NO. : 06AAACS1194G1ZJ

Services

|

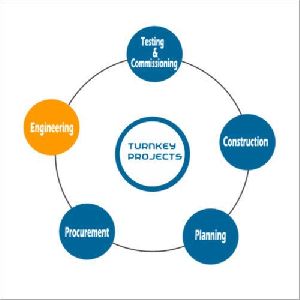

SSV Vessels Pvt Ltd undertakes turn key projects for Designing, Supplying, Installing Commissioning of LPG Bottling Plants. The plants are designed in accordance with PESO norms and guidelines.

The company installs bottlings plants conforming to Latest LPG Guidelines as practiced in country of Operation. For Indian Subcontinent M/s SSV Vessels Pvt Limited installs OISD 169 and OISD 144 Compliant Plants. All key features of the above guidelines are followed by us along with the statutory requirements of PESO and other Government of India regulations.

M/s SSV Vessels Pvt Ltd installs both Carousal Operated and Filling machine operated plants. Customization of machinery as per customer intended production capacity is also considered by us while proposing the nature of plant suitable for the client. From manually operated to semi automatic operation to fully automized plants M/s SSV Vessels Pvt Ltd provides all solutions to client. read more... |

|

SSV Vessels fabrication division handles a wide range of custom fabrication projects including conveyors, Hoppers, Manifolds, Skids and other complex equipments that are specific to your application. Our skilled & experienced team uses the latest in welding and fabrication technology to bring you perfect pieces every time.

Structural Fabrication SSV Vessels handles the building of all structural steel projects. All of our structural products are designed with safety in mind and rated to meet your load and weight requirements.

Heavy Fabrication SSV is capable of large scale custom metal fabrication projects of any size including industrial structure, large capacity water storage tanks and more.

Finishing Whether its Blasting, Painting or Powder Coating you want, SSV Vessels Private Limited has all the technological know-how to satisfactorily provide cost effective and durable solutions to provide surface protection solution to our clients. read more... |

|

We also undertake turn-key projects that involve Supply, Erection, Testing and Commissioning and Servicing of LPG Bottling cum Blending units, Propane / LPG bulk storage Industrial Installations.The Company has executed many such turn-key projects in India & abroad.

Our scope of work includes –

|

|

Since Our expertise already lies in the field of Design/ Manufacturing / Installation / Plant Commissioning / Maintenance / Mechanical work completion, we have also extended our services to Audits & Inspection, Testing & Certification or Re-certification of Propane / LPG / Pentane / Petroleum class A/B Bulk Storage installations. We also cater to needs of Mobile road tankers for Inspection and Certification.

Since its expertise already lies in the field of Design/ Manufacturing / Installation / plant Commissioning / Maintenance / Mechanical work completion, it has also extended its services to Audits & inspection, testing & certification or recertification of plants of Propane / LPG / Pentane / Petroleum class A/B Bulk Storage installation, Road Tankers, equipment & machinery involving in mounded bullets, Horton Spheres, used for storage of LPG, pressure vessels, rail wagons, piping for petroleum products including those requiring low temperature application, reticulated gas systems, all conforming to National & International standards.

|

|

Preventative Plant Maintenance Approach The Oil and Gas Industry has now shifted from a Reactive approach to a Preventative or more so a Proactive approach in the Maintenance of its Pipeline and In-Process Equipment. Adoption of preventative maintenance helpsin minimising unplanned downtimes.

SSV Vessels Pvt Ltd with its rich experience in Oil and Gas sector has ample knowledge to provide both Preventive and Reactive solutions of Pipeline and Equipment Maintenance to its clients.SSV Vessels provide repair, maintenance & modification solutions of oil and gas pipelines for both Off shore and Onshore Installations.

We deal with Time based and Condition based maintenance of your plant & Time and this can be achieved through –

SHUTDOWN We offer full-service industrial plant maintenance and shutdown planning that allows the continuity of plant/facilities management and procedures.

During the critical period that lead to the shutdown, having a full-service industrial maintenance plan allows our Clients to focus on the upcoming shutdown tasks and spend less time on contract management.

OUTAGES We use scheduled plant outages to investigate and identify process systems maintenance issues that could affect plant viability. We conduct thorough visual examinations and service inspections; perform operational checks & tests to establish mechanical & electrical (M&E) equipment maintainability, reliability and availability. Our outage services also enhance a facility’s profitability by making the most productive use of capital resources.

TURNAROUNDS While no two turnarounds are ever the same, you can rest assured that we will approach each project with the same professional intensity. We can manage the entire turnaround from start to finish, performing heat exchanger maintenance, vessel inspection, along with valve and piping replacements. We also understand that turnarounds are costly and typically the most significant portion of the plant’s yearly maintenance. So we work quickly, efficiently yet safely.

PPM offers the following industrial shutdown, turnaround, and outage services:

|

|

Adequate designing of a pressure vessel or a layout enhances the productivity of the equipment and the process, manifold. This finally converts to benefits for an organization.

SSV Vessels brainstorms with client to understand the nature of its business activity. Accordingly, a work process flow chart is designed that is suitable for the client’s requirement. Once the concept is finalized the work process flow chart is put to design in context of the requirement and layout and placement of in-process equipment is objectified.

SSV Vessels has most modern design engineering facilities. Pressure Vessels are designed by using latest software.Plants layout are designed keeping the best suitable ergonomics for the client, minimizing land requirement and maximizing client benefit by optimum utilization of resources. read more... |